Steel is an alloy of iron with a small amount of carbon. Steel comes in different grades based on the percentage of carbon it contains.

- Low-carbon, or mild steel contains 0.3 % or less carbon by volume.

- Medium-carbon steel contains 0.3% to 0.6% carbon.

- High-carbon steels contain more than 0.6% carbon.

Small amounts of other alloying materials such as chromium, manganese or tungsten are also added to produce many more grades of steel. These alloys modify the properties of the steel, such as tensile strength, ductility, malleability, durability, and thermal and electrical conductivity. Differences between Hot Rolled Steel and Cold Rolled Steel

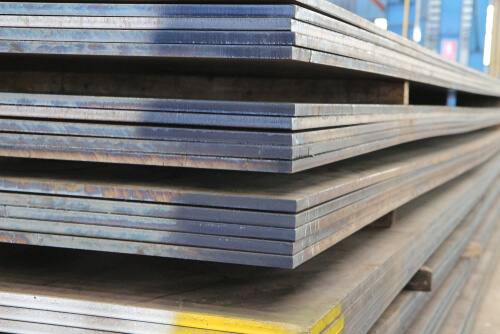

Most steel is manufactured in one of two basic ways: hot rolling or cold rolling. Hot rolled steel is mill process by which the steel is roll pressed at a high temperature. Generally, the temperature for hot rolled steel exceeds 1700°F. Cold rolled steel is a process by which steel is roll pressed at room temperature. It is important to note that both hot rolled steel and cold rolled steel are not steel grades. They are the pre-fabrication techniques used for a variety of steel products.  Hot Rolled Steel Process

Hot Rolled Steel Process

Hot rolled steel involves forming and rolling the steel slabs into a long strip while heated above its optimum rolling temperature. The red-hot slab is fed through a series of roll mills to form and stretch it into a thin strip. After forming is complete, the steel strip is water cooled and then wound into a coil. Different water-cooling rates develop different metallurgical properties in the steel. Normalizing hot rolled steel at room temperature allows for increased strength and ductility. Hot rolled steel is typically used for construction, railroad tracks, sheet metal, and other applications that do not require attractive finishes or precise shapes and tolerances. Cold Rolled Steel Process

Cold rolled steel is heated and cooled just like hot rolled steel but is then further processed using annealing or temper rolling to develop higher tensile strength and yield strength. The additional labor and time for processing adds to the cost but allows for closer dimensional tolerances and provides a wide range of finishing options. This form of steel has a smoother finish and is used in applications requiring a specific surface condition and dimensional tolerance. Common uses for cold rolled steel include structural parts, metal furniture, home appliances, as well as auto parts and technical applications where precision or aesthetics is necessary. Grades of Hot Rolled Steel

Hot rolled steel comes in several grades, or standards, set by either the American Society for Testing and Materials (ASTM) or the Society of Automotive Engineers (SAE). ASTM steel grades begin with the letter [A" which stands for ferrous metals. The SAE grading system (also sometimes known as the American Iron and Steel Institute or AISI system) uses a four-digit number for classification. Plain carbon steel grades in this system start with the digits 10, followed by two digits denoting the carbon concentration. The following are common grades of hot rolled steel. Note that some products are offered in both hot rolled or cold rolled options. A36 is the ASTM standard for one of the most popular hot rolled steels (it also comes in a cold rolled version, which is much less common). This low carbon steel maintains less than a 0.3% carbon content by weight, 1.03% manganese, 0.28% silicon, 0.2% copper, 0.04% phosphorus, and 0.05% sulfur. - The low carbon content within A36 allows it to be easily machined, formed, and welded, making it useful in a wide range of applications.

- However, since A36 does not contain large amounts of chromium and nickel it only provides average corrosion resistance.

- Hot rolled A36 steel bar maintains excellent mechanical properties and is simple to fabricate through conventional methods including welding, hot forming, and mild cold forming.

- It is characterized by its radius corners, due to shrinkage when cooling, compared to the sharp corners of cold rolled steel.

- It also retains scaled surfaces due to the extreme temperature cooling process.

- ASTM A36 is chemically like AISI/SAE 1018 steel, which is most used in the cold rolled version.

- The main differences in each grade come down to the overall metal qualities and the advantages that they represent for each specific application.

- A36 steel is less expensive than 1018 with similar, but less striking finish and machinability characteristics.

- Due to its significant cost advantages, A36 steel is commonly utilized for heavy duty construction and equipment applications.

Industries that regularly utilize A36 hot rolled steel, include: - Bridge construction

- Automotive

- Construction

- Heavy equipment

- Oil & gas

A36 Hot rolled steel bar is used in numerous applications, including: - Truck frames

- Agriculture equipment

- Shelving

- Walkways, ramps, and guard rails

- Structural support

- Trailers

- General fabrication

Check out Industrial Metal Supply`s ASTM A36 steel products. We offer ASTM A36 angle, rectangular bar, round bar, square bar, beam, channel, pre-cut, and tee options.

Next to A36, AISI/SAE 1018 is one of the most common grades of steel. Typically, this grade is used in preference to A36 for bar or strip forms. 1018 comes in both hot rolled and cold rolled versions, though the cold rolled is more commonly used. Both versions have better strength and hardness than A36 and are better suited for cold forming operations, such as bending or swaging. 1018 contains only 0.18% carbon and 0.6-0.9% manganese, which is less than A36. It also contains traces of phosphorous and sulfur, but fewer impurities than A36. Typical uses of 1018 HR (hot rolled) carbon steel bars include: - Gears

- Pinions

- Ratchets

- Oil tool slips

- Pins

- Chain pins

- Liners

- Studs

- Anchor pins

IMS stocks a variety of 1018 steel products including 1018 hex bar, rectangle bar, round bar, and square bar.  1011 Hot Rolled Steel Sheet

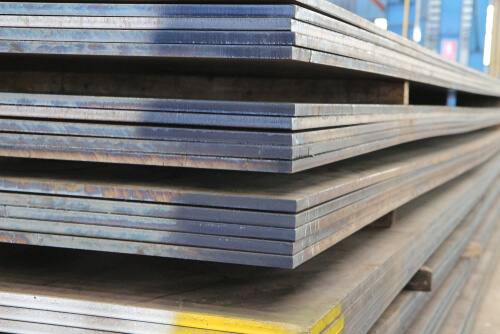

1011 Hot Rolled Steel Sheet

AISI/SAE 1011 is the standard specification for a high-strength, low-alloy hot-rolled carbon steel for the sheet and plate forms of A36. This standard replaces the old A569 CQ type steel which was withdrawn by ASTM as of 2010. 1011 Hot rolled steel sheet and plate provides a rougher surface than cold rolled steel and plate. When galvanized it is also used in applications where corrosion resistance is a necessity. High strength and highly formable HR steel sheet and plate is also easy to drill, form and weld. Hot rolled steel sheet and plate is available as standard hot rolled or as hot rolled P&O. Hot rolling utilizes large ingots and large reduction rolling, which not only improves production efficiency, but also creates conditions for increasing rolling speed and achieving a continuous and automated rolling process. Some of the other benefits associated with 1011 hot rolled steel sheet and plate include: - Increased malleability

- Numerous applications

- Less expensive than cold rolling

- High rate of production

Durable, adaptable, and easy to work with, steel sheet and plate can be used to create a huge variety of products and structures. Common applications for 1011 steel plate and sheet include: - Building & construction

- Automotive & transportation

- Shipping containers

- Roofing

- Appliances

- Heavy equipment

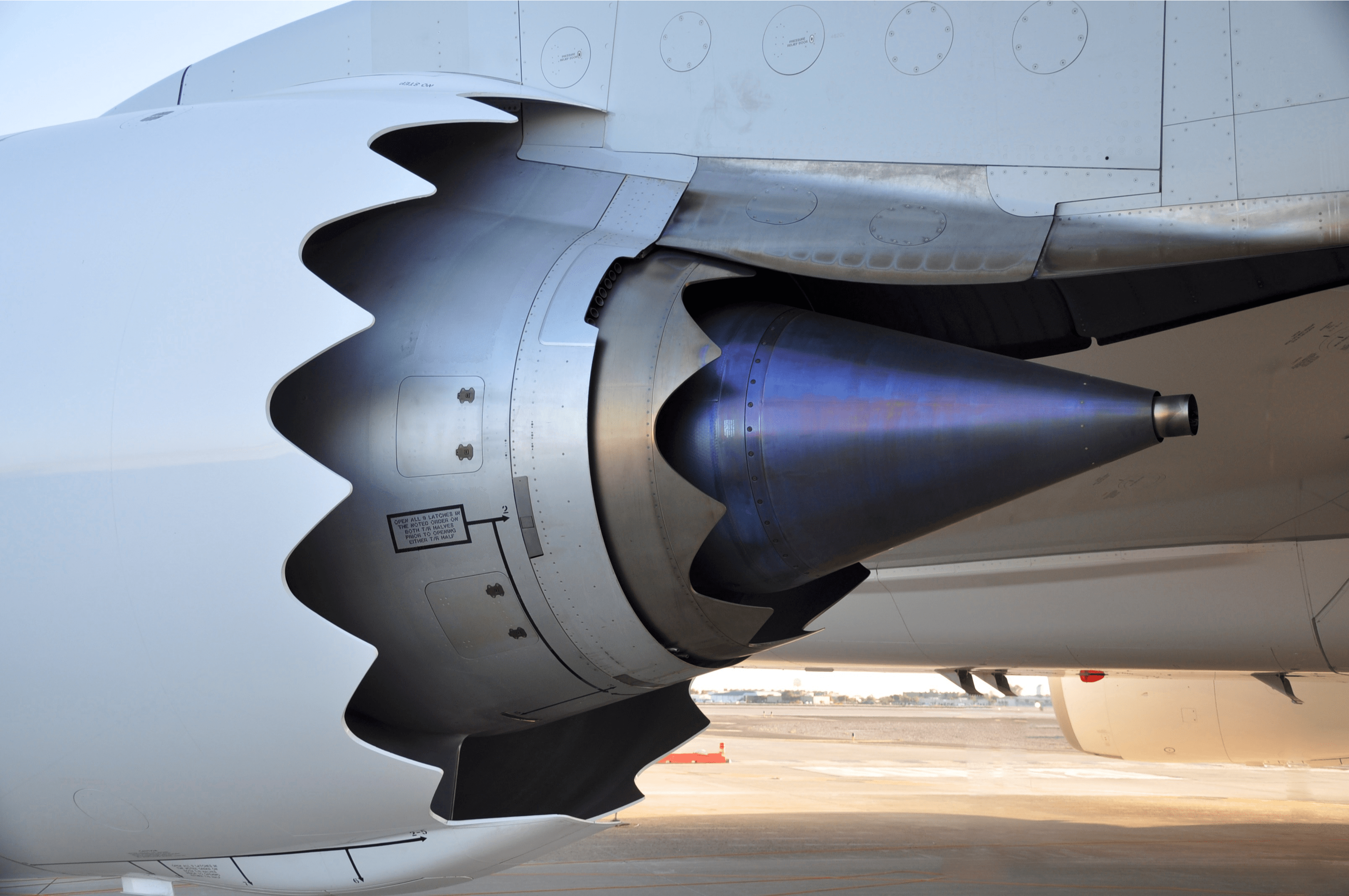

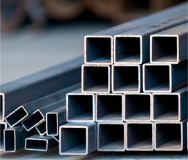

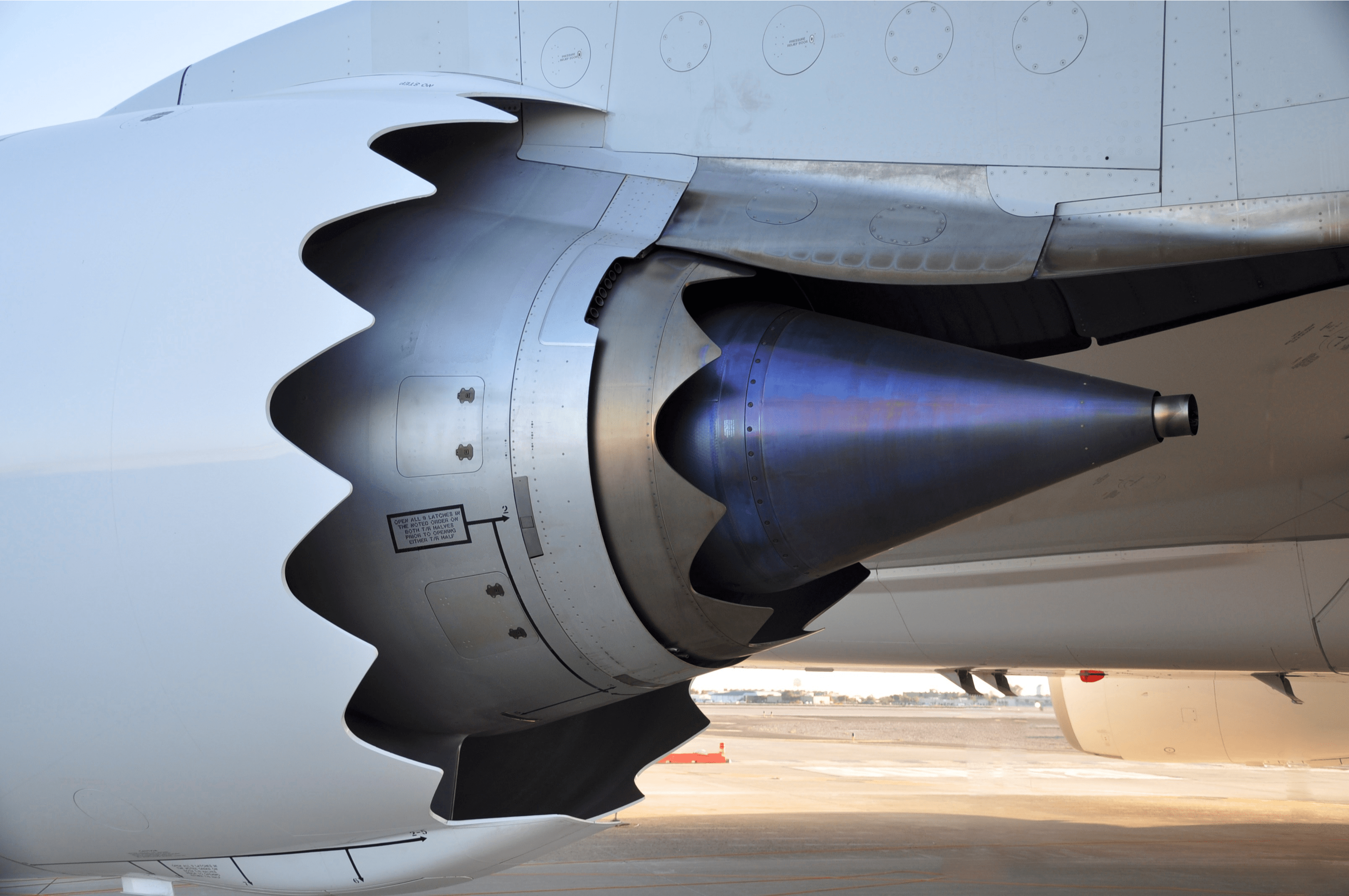

The ASTM A513 specification is for hot rolled carbon steel tubes. Hot rolled steel tubes are manufactured by passing heated sheet metal through rollers to achieve specific physical dimensions. The finished product has a rough surface finish with radiused corners, and either a welded or seamless construction. Because of these factors, hot rolled steel tube is best suited for applications that do not require precise shapes or tight tolerances  Hot rolled steel tube is easy to cut, weld, form, and machine. It is used in numerous industrial applications, including:

Hot rolled steel tube is easy to cut, weld, form, and machine. It is used in numerous industrial applications, including: - Engine mounts

- Bushings

- Building construction/architecture

- Automobiles and related equipment (trailers, etc.)

- Industrial equipment

- Solar panel frames

- Home appliances

- Aircraft/aerospace

- Agricultural equipment

A513 steel products are available in a variety of shapes including A513 rectangle tubing, A513 round tubing, and A513 square tubing. Hot Rolled ASTM A786 Steel

Hot rolled ASTM A786 steel is hot-rolled with high-strength. It is commonly manufactured for steel tread plates, ideal for flooring and treadways. 1020/1025 Hot Rolled Steel

Ideal for construction and engineering applications, 1020/1025 DOM steel can be used for tool and die applications, machinery parts, and auto equipment/industrial equipment uses. Your Trusted Hot Rolled Steel Resource

Hot Rolled Steel Process

Hot Rolled Steel Process

1011 Hot Rolled Steel Sheet

1011 Hot Rolled Steel Sheet